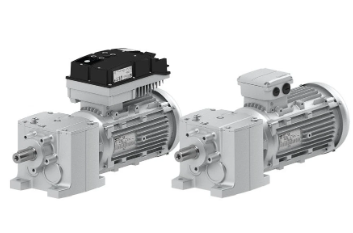

Gearmotors combine motor and gearbox in a single, integrated unit for simplified installation and optimized performance.

Our range covers AC and DC gearmotors in parallel shaft, right-angle, and inline configurations for conveyor systems, packaging equipment, automated machinery, and process applications.

Please contact us to find the best gearmotor for your application!