What do all those motor acronyms even mean?!?

Posted by Beckie Sullivan on Sep 16th 2022

TEFC, TEAO, ODP, TENV, EXP(L), C-Face, Footed, Footless, and Resilient Base….what do those even mean?

Imagine this; you need to buy a motor and you already know your torque and horsepower requirements. You begin your search online only to be bombarded with acronyms, TEFC vs. ODP or maybe you should go with a C-Face model? Unless you know exactly what you need to order, purchasing a motor online can be a hazardous and potentially expensive endeavor.

We’re here to shed a little light on those confusing terms and hopefully make your motor purchasing experience a little less “hairy.”

TEFC: Totally Enclosed Fan Cooled

Expect to see a cover on the non-shaft side of the motor which protects the motor’s windings from external air. Rather than cooling the motor’s windings directly with air, and potentially other contaminants, the fan forces air over the cooling fins to regulate temperatures. This is the most versatile of globally used type of motor and can be found in farming, oil well, pool pump and other sever duty applications.

TEAO: Totally Enclosed, Air Over

Generally limited in nature being solely used in fan/blower applications where the motor is located with the air stream. The motor remains dust-tight while being cooled by pre-existing fans used to provide air movement for the entire application. This cost efficient solution is often used to power direct-coupled fans and generally will be positioned directly in the area in which the fan is blowing air.

TENV: Totally Enclosed, Non-Ventilated

Similar to the TEFC, a TENV motor is completely enclosed but does not include a cooling fan. These motors are specifically designed to dissipate heat, either through smaller frames or heavy ribbing to act as an external heat sink. The tight enclosure prevents the free exchange of air but potential contamination entering through the shaft limits these motors to indoor/outdoor applications that do not allow for hazardous, corrosive, or explosive damage.

This type of motor features angled vents which allow air flow around the windings while preventing water from dripping in. While these motors are not as protected against external contaminants, they do fair better with thermal runaway with help from an internal fan. Typically ODP motors are used for indoor applications in relatively clean, dry locations.

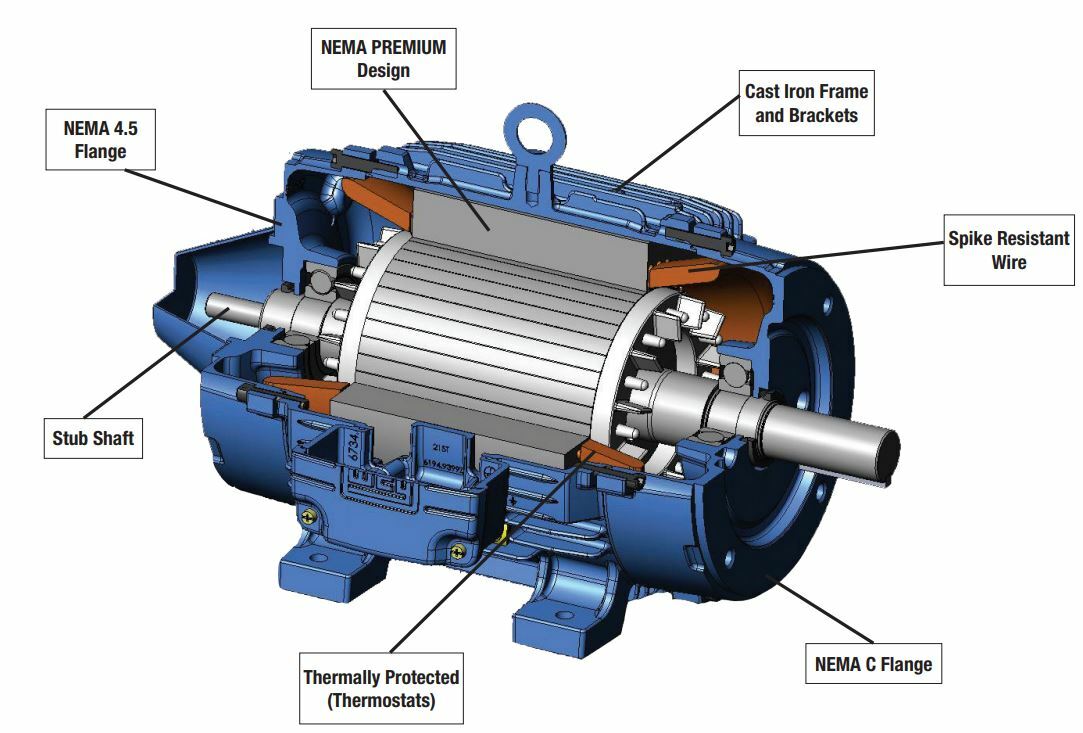

One of the more commonly used frames, C-Face is designed with installation in mind. Having a flat surface machined onto one side allows for direct-coupling with equipment while the weight of the motor is cantilevered with the help of a heavy duty flange. Of course, this method is not useful for large motors and is rare in HP ranges over 20HP.

Specifically designed, often with cast iron material, to withstand internal explosions from combustible gases or dust; such as: utility gas plants, dry cleaning facilities, drip tanks, gas stations, flour mills, firework plants and hazardous material production plants. For safe operation, the maximum motor operating temperature must be below the ignition temperature of surrounding gases or vapors.

- Explosionproof (XP): A machine designed to withstand an explosion of a specified vapor, gas, or dust, inside the motor casing and prevent the ignition outside the motor by sparks, flashing, or explosion.

- Drip-proof Guard (DPG): An open drip-proof machine in which all openings giving direct access to live metal or rotating parts (except smooth rotating surfaces) are limited in size by the structural parts, or by the screens, baffles, grilles, expanded metal, or other means to prevent accidental contact with hazardous parts. Openings giving direct access to such live or rotating parts shall not permit the passage of a cylindrical rod 0.75 inch in diameter.

- Totally Enclosed Water Cooled (TEWC): A totally enclosed machine which is cooled by circulating water and with the water or water conductors come in direct contact with the machine parts.

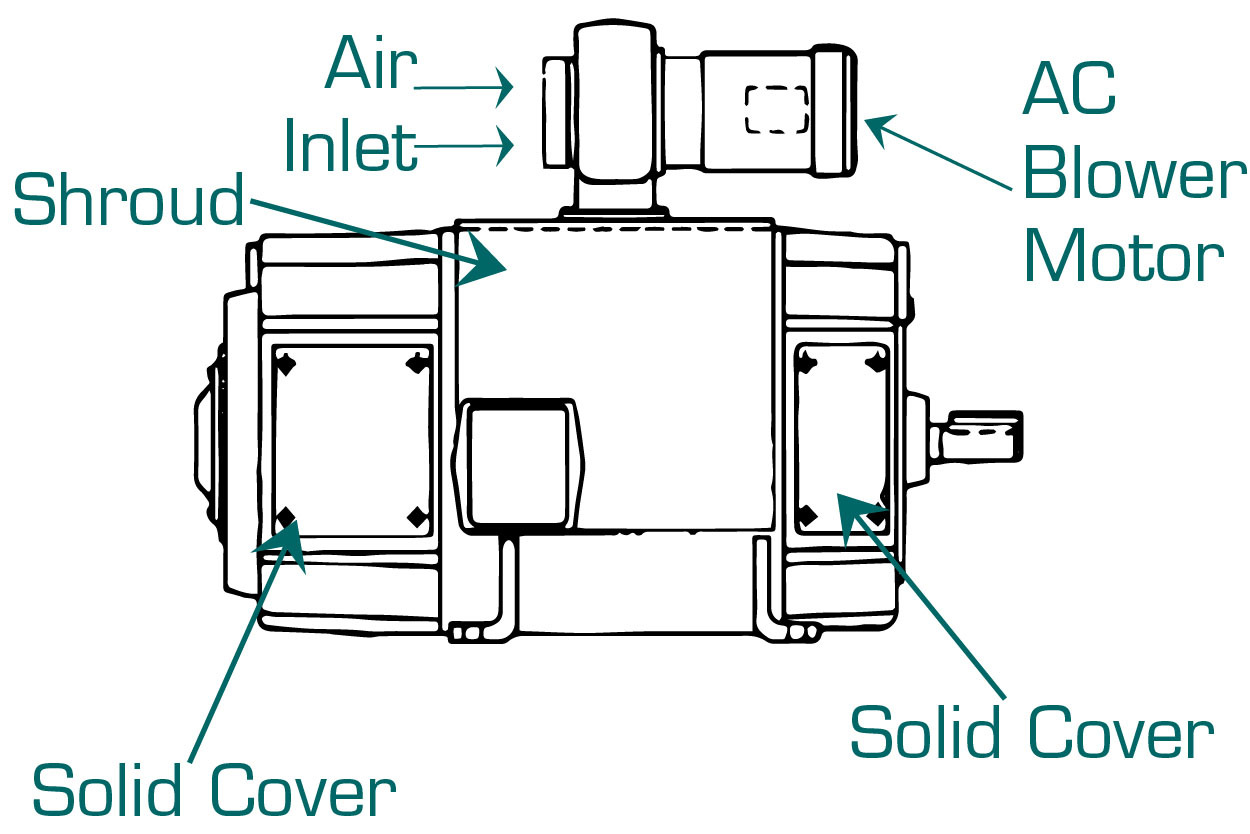

- Totally Enclosed Water-to-Air Cooled (TEWAC): A totally enclosed machine which is cooled by circulating air which, in turn, is cooled by circulating water. These motors are provided with a water-cooled heat exchanger for cooling the internal and a fan(s), integral with the rotor shaft separate, for circulating the internal air. (Design not offered in U.S. MOTORS® brand product line.

- Washdown Duty: A machine designed specifically for the food processing industry and other applications that are routinely exposed to washdown, chemicals, humidity, and other severe environments.

The term is applied to a motor has feet or plate that the weight of the motor rests upon. The feet are commonly bolted to bottom of the motor body

This is the opposite of footed, which means these motors generally come with a C-face mount.

Another term for a cradle style base, which is formed steel that formed into a “U” shaped cradle supporting the motor.

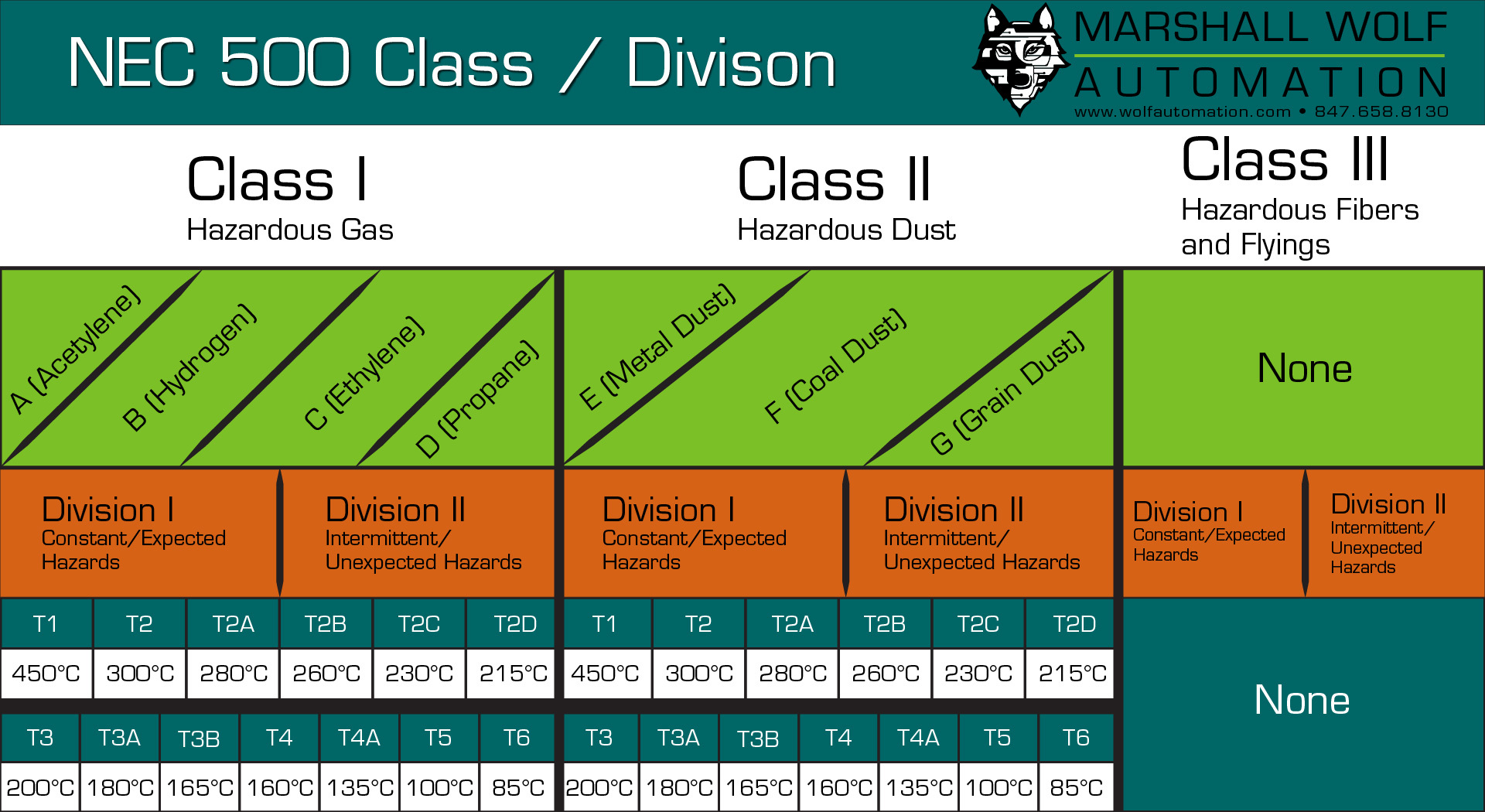

Unlike other applications, EXP(L) rated motors require additional classifications which will differentiate between countries. In North America, we tend to follow the NEC standard of hazardous locations which classifies explosive environments by Class (Gas/Dust/Flying’s and Fibers) the class “Sub-Groups” and Divisions (how often the hazard is present). It is suggested that EXP(L) motors are configured by either a Safety Engineer or by an insurance company.