New From Novus - TL400 Non-intrusive Laser Sensor

Posted by Theresa Hoffman on Jan 11th 2024

.

Monitoring and measurement are two critical aspects of safety and quality control. Sensors are a great tool to collect data for both. Let’s focus on sensor applications for level and volume measurement.

Intrusive vs Non-Intrusive

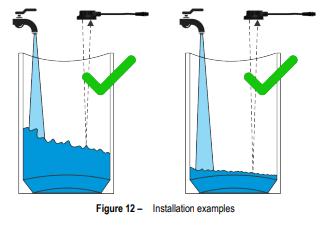

Intrusive sensors have contact with materials while non-intrusive don’t.

Liquids, grains, fluids and bulk solids are all places that are more desirable for non-intrusive sensor.

Why? They avoid contamination by not contacting the material.

They also improve safety in hazardous environments by measuring the level and volume of material in hazardous environments.

Although both types of sensors have benefits, non-intrusive are typically easier to install and maintain.

Let’s discuss why Novus TL400 is ideal for these types of applications.

Laser ToF is a technology that uses lasers to measure the distance between an object and the sensor.

Laser ToF

Novus carefully designed its TL400 series with laser ToF technology because it is more advanced than standard laser technology.

Laser ToF sensors are more versatile than traditional laser sensors.

They are more accurate and precise, able to measure distances with a resolution of millimeters or less.

Finally, they are very fast, making them ideal for real-time measurement applications.

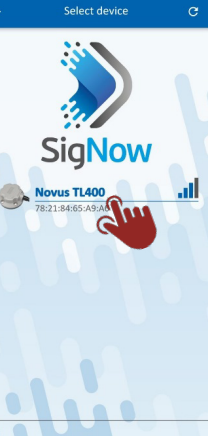

SigNow App

Novus TL400 data is sent to SigNow app which is compatible with Android and iOS.

The app keeps you informed on quality control, safety monitoring, and remote data collection.

This means that if there is a change in flow rate of chemicals, a leak in pipelines or any manufacturing defects, you will be notified on your phone.

By combining the data collection and analysis capabilities of the TL400 with the collaboration feature of SigNow, you can improve efficiency, productivity and safety.

Marshall Wolf Automation is an authorized distributor for Novus products. Contact our technical support team with your application details and we’ll be happy to find the right fit!