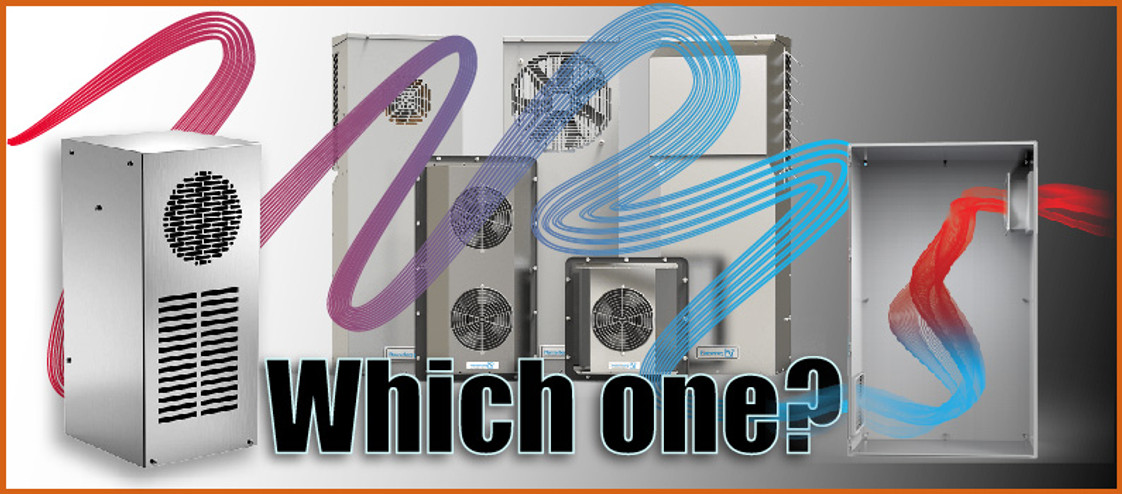

Filterfan®, Heat Exchanger, Chiller or a Cooling Unit?

Posted by Morgan Spano on Jun 11th 2020

I’m Confused. Do I Need a Filterfan®, Heat Exchanger, Chiller or a Cooling Unit to Manage Temperatures in my Enclosures?

You know it’s too hot in your enclosure but what product do you need to cool it down? Below you will find a quick overview with a short checklist that will help you narrow down which product is best.

Need more help? Our in-house tech support is readily available to help you!

Will a Filterfan® work for my application?

Filterfans® force surrounding air into the electrical enclosure so that a slight overpressure builds up inside the enclosure. The surrounding air enters the enclosure via the Filterfan® which ensures that it is filtered.

● The ambient (outside of the enclosure) temperature is lower than inside the enclosure and stays within an acceptable range

● The application is in a clean, non-hazardous environment

Extra Bonus:

Filterfans® are very cost-effective and work great if you need multiple configurations, they can be located in a range of locations within complex enclosure configurations.

We recommend installing Filterfans® in the lower third of the enclosure and the exhaust filter as close to the top as possible. This helps avoid hot spots within your enclosure.

Would an Air to Air Heat Exchanger be best for my requirements?

Air to air heat exchangers are used to remove heat from electrical enclosures. They do this by transferring heat from inside the enclosure to the external air.

● The ambient (outside of the enclosure) temperature is lower than the temperature I need inside my enclosure

● I need a total separation between ambient air and the enclosure

Extra Bonus:

Air to air heat exchangers are energy efficient, generally using 60% less energy than an A/C type cooling unit.

Do I need a Cooling Unit?

Pfannenberg cooling units work as a heat pump that basically pumps the thermal energy transferred from the enclosure up to a higher level of temperature. The air inside the enclosure is cooled down by the evaporator and at the same time dehumidified.

● The ambient (outside of the enclosure) temperature is higher than the target internal temperature of the enclosure

● Active cooling is required

Extra Bonus:

If you have a NEMA rating that is required, closed loop cooling can maintain the NEMA rating of the enclosure. For harsh environments where ambient air must be kept out of the enclosure cooling units seal out the ambient air, cooling and re-circulating clean, cool air throughout the enclosure.

When would I need an Air to Water Heat Exchanger?

Air to water heat exchangers use a water source to remove the heat from the enclosure. The heat is transferred to fluid and the heated fluid is them removed, adding no heat to the ambient (outside of the enclosure) environment.

● There is a chilled water source readily available at the enclosure

The application has extreme conditions; high ambient temperatures, extremely dirty or caustic or other issues that make other solutions unusable

Extra Bonus:

There is no heat transfer to the ambient environment so there is no need to de-rate the units in high ambient applications.

When would I need to use a Chiller?

Chillers use a refrigeration cycle to remove collected heat from a circulating liquid. As the liquid moves through tubes and pipes it absorbs the heat generated by equipment and processes. The generated heat is transferred back to the chiller where it is dissipated. Fluid is cooled and sent back into the system.

- You need to manage higher heat loads that exceed traditional enclosure cooling methods

- Precise temperature control is required in the manufacturing process

- Large fluctuations in heat load requirements need to be managed

- The source of cooling can be located separately from harsh environments