Assembled in the USA! Lenze B.L.U Line Gearmotor

Posted by Theresa Hoffman on Sep 22nd 2025

When your production line is running full speed when suddenly a critical component fails, you place the order for a replacement, only to find out the lead time is months away. Operations stall, deadlines slip, and frustration mounts. In today’s fast-paced world of automation, long delays aren’t just inconvenient — they can be costly.

That’s where Lenze steps in with the B.L.U. Line. This gearmotor and drive package portfolio is assembled right here in the USA, designed to shorten delivery times while giving you reliable, high-performance components you can count on. It’s a solution built for speed, efficiency, and peace of mind.

Why B.L.U. Line Stands Out

The entire B.L.U. Line portfolio is assembled at Lenze’s U.S. headquarters, which means you can count on robust inventory, shorter lead times, and the comfort of local support.

Standard configurations ship in under four weeks, making the process predictable and stress-free. And when you’re unsure which setup is the right fit, Lenze’s ordering guide takes out the guesswork by pointing you toward the best configuration for your machine.

What’s Inside the Portfolio?

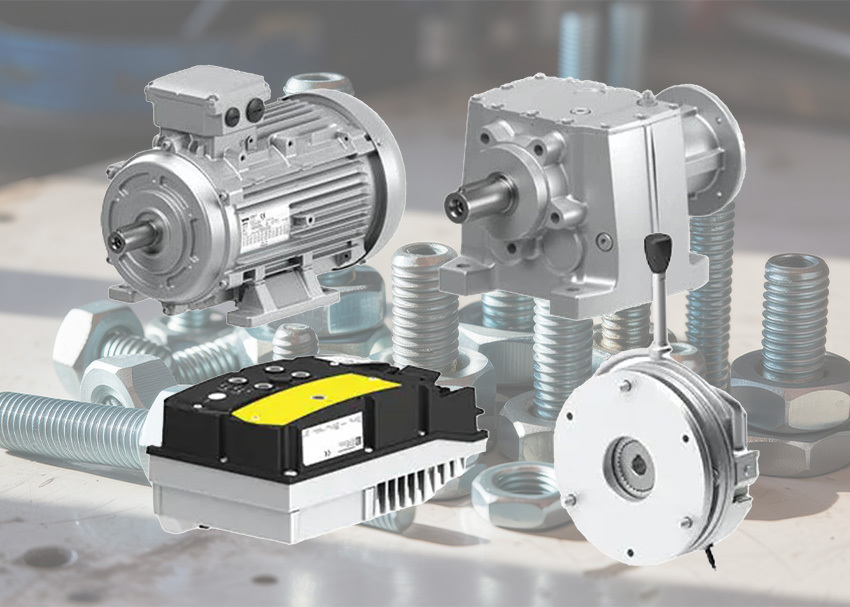

The B.L.U. Line isn’t just about speed — it’s about choice and performance. At its core is the m550 motor, a three-phase AC motor available in both IE2 high efficiency and IE3 premium efficiency. Covering a power range of 0.5 to 3 horsepower (0.37 to 2.2 kW), it’s built for optimal performance and reliability, even in demanding industrial settings.

Working alongside the motor is the g500 gearbox, which can be configured as bevel, helical, or shaft-mounted. Whether you need inline, parallel shaft, or right-angle designs, the g500 delivers smooth operation thanks to high permissible radial forces, closely stepped ratios, and low backlash.

Completing the lineup is the i550 motec decentralized VFD. Rugged, efficient, and flexible, it mounts directly on the motor for ultimate convenience. Its regenerative feedback function even eliminates the need for brake resistors, simplifying installation and improving efficiency. And for applications where holding power is essential, an optional holding brake provides reliable stopping strength when you need it most.

Bottom Line

The Lenze B.L.U. Line was created to help you avoid long waits, reduce downtime, and keep your machines running at their best. With local assembly, fast shipping, and a versatile set of options, it’s designed to make your job easier and your operation more reliable.

Want to see how it can support your next project? Contact us for more information and ordering details.